2019-11-23 03:29:48

Before the UV laser marking machine can available in the market, most companies will choose inkjet printers for metal and non-metal materials processing because it's cheap and easy to use.

However, convenience also brings a lot of troubles, such as

The nozzle of the printer will be going to blocked after using some time; The nozzle will leak ink, which will cause the production environment to become dirty and increase the workload of workers;

The coding effect is not wear-resistant can be easily scratched or the QR code is fuzzy after scratched and difficult to identify;

The high maintenance rate increases the cost of enterprises and so on issues.........

With more and more problems caused the production efficiency decline and the enterprise's technicians have to find another alternative technology.

Above is the complaint we received from our customer who using an inkjet printer.

At the same time, many companies are beginning to experiment with laser marking technology.

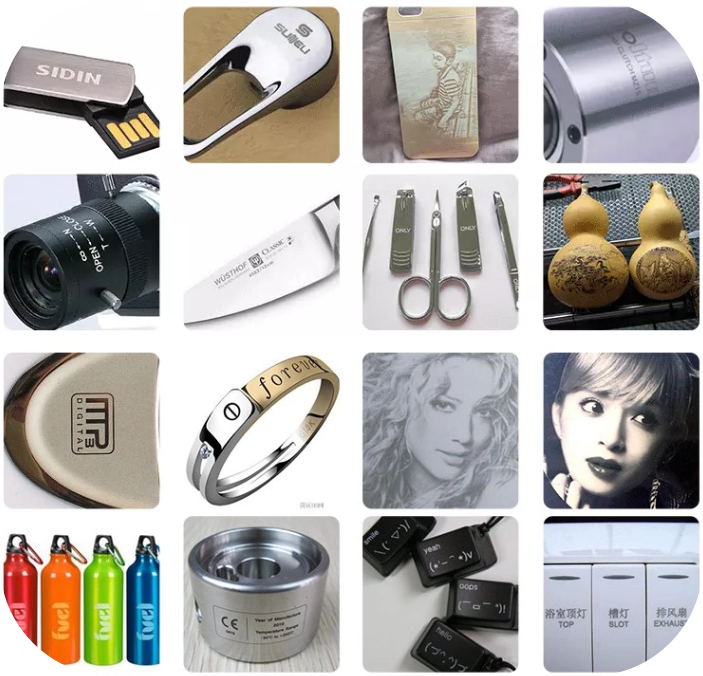

General metal products and the companies that do not pursue fine laser marking processing quickly found a laser marking machine what suitable for their application, and replaced the inkjet printers they using for current production soon.

However, the materials and requirements are diverse. There are always have someone who pursues more than general laser marking, requested more fine process. And also, some plastic was not suitable to marked by Fiber laser or CO2 laser, due to Fiber and CO2 both are hot laser beam which will cause burning when marking on the plastic surface. So before the new laser technology arrival, the plastic product company that can do nothing can only continue to use the printer while looking for new solutions.

Plastic is a Complex material, thus basically we will request to do a test before confirming the order. Unless you have used the same machine to do laser marking before. Below are the samples engraved by CO2 Laser.

As laser technology becomes more and more mature, and the laser engineer team continues to explore and test, the pursuit of a higher level of laser marking technology.

Finally exciting news appeared-UV Laser!

UV laser is of the cold light source and with a unique low-power laser beam and short-wavelength 355nm. And Fiber is 1064nm, CO2 is 10.64um. The advantages of UV laser was that High repetition rate focus, smaller spot, belongs to cold process with a little heat affecting, good beam quality, it can achieve hyperfine marking.

Most materials can absorb ultraviolet laser, it is widely applied on industrials; Especially suitable for the high-end market of ultra-fine processing. As I mentioned above, for example, the plastics market: Such as PP, PE, PBT, PET, PA, ABS, POM, PS, PC, PUS, EVA, etc, can also be used in plastic alloys such as PC/ABS and other materials.

The UV laser with cold light laser beam, therefore there is no burning problem, pollution-free, non-toxic, high marking speed, high efficiency, the machine performance is stable, low power consumption.Better than ink coding and no pollution.