2024-09-25 01:15:22

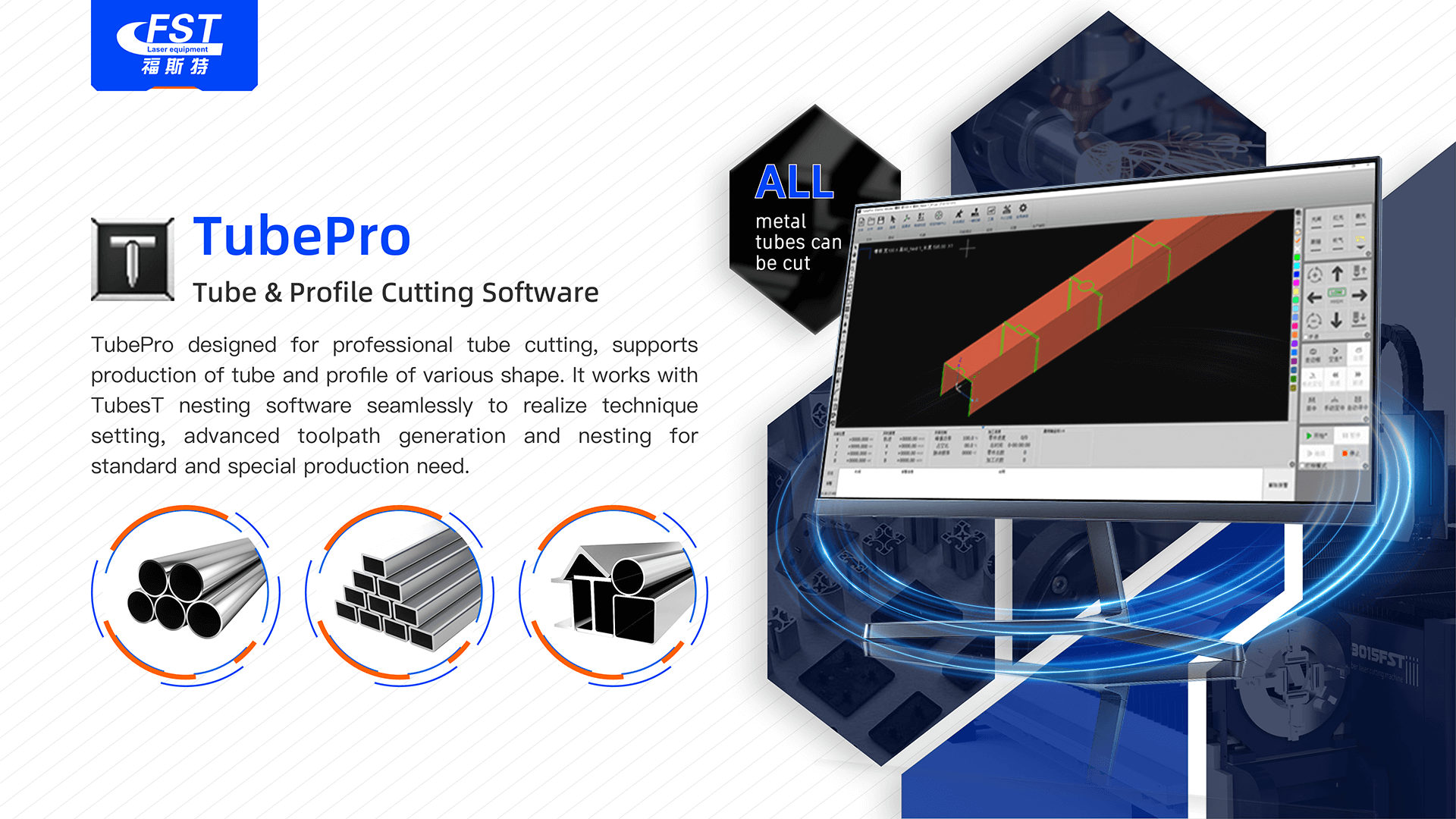

In modern manufacturing, fiber laser cutting machines are widely used for their efficiency and precision. As technology advances, the intelligence of these cutting machines continues to improve. To enhance both efficiency and cutting accuracy, the Baichu control system has become increasingly important as the core control system for fiber cutting machines, playing a vital role in driving industry progress. Foster Laser will guide you through the role of TubePro software in tube cutting machines:

TubePro Main Features:

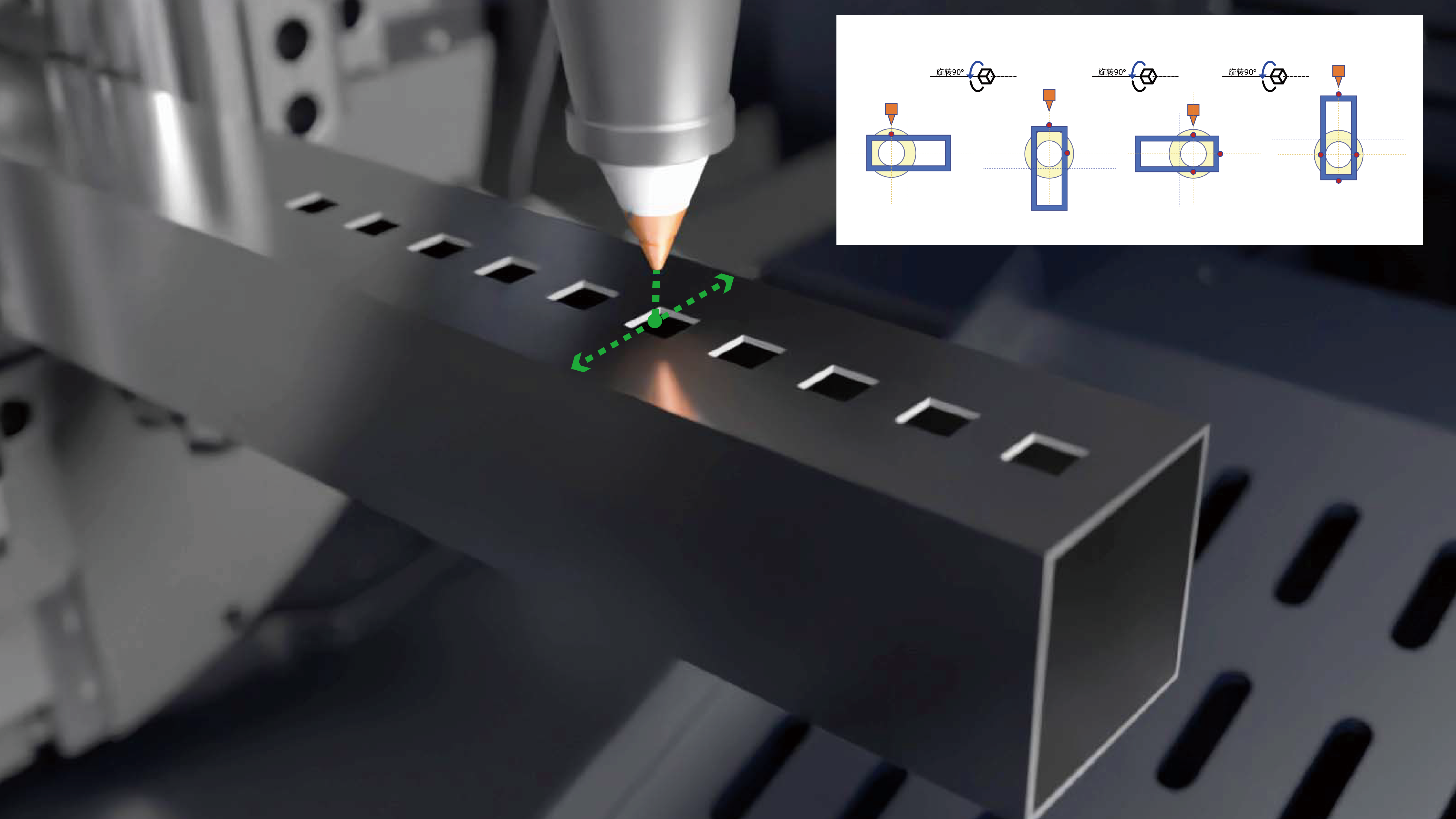

01 Auto Find Tube Center in Production

02 Workpiece and Floating Coordinates

03 Seven-Axis Tube Delivering

04 Tube Holder

05 Corner Technique

06 Active Control at Corner Cutting

07 Quick Frog-Leap

Free Form Tube & Profile Production

Automatic centering during processing

TubePro can obtain the deviation between the center of the pipe and the center of rotation of the chuck by collecting Z-axis information in real time during processing. The graphics to be cut are compensated in real time to achieve high precision machining.

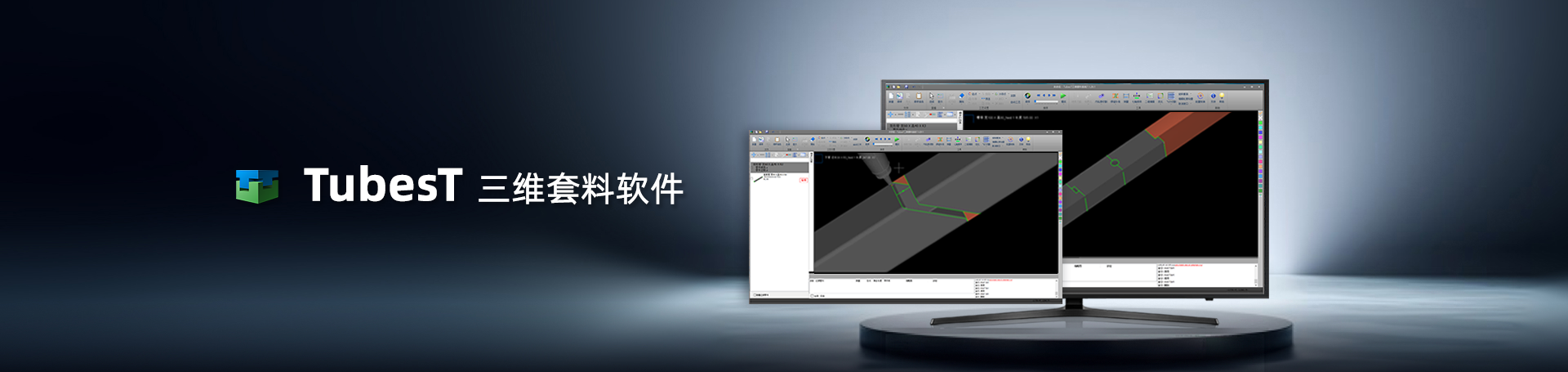

TubesT is a 3D tube nesting software designed for Cyptube/TubePro laser cutting system. From parts drawing and modification, full type compensation,strategic nesting to report generation,using TubesT will meet and exceed your production needs.

TubesT-Lite is a free software to generate toolpath for FSCUT tube cutting system It's designed for CypTube/TubePro. can import part from external igs file, draw the part of standard shape and array-nest the part on the tube.

The TubePro control system really excels in Tube Laser cutting machines, Plate and Tube integrated Laser Cutting machines, Fully Automatic Laser Tube Cutting Machines, and Semi-Automatic Laser Pipe Cutting machines. Its precise cutting control, fast response, and high stability significantly enhance cutting quality and efficiency. The system features a user-friendly programming interface that allows operators to easily set and adjust various parameters, adapting to different processing needs. Additionally, the smart design of the Friendess system helps improve automation levels, reducing the complexity of manual operations and further boosting production efficiency. If you need our services, please contact us!