2019-11-26 19:24:35

Laser engraving machine refers to the operation method of connecting laser equipment to laser engraving software and inputting the artwork into automatic engraving. At present, a laser engraving machine is a most mature and widely used technology in the field of laser processing. Using this technique, any complex graphics can be carved. It can carry out hollow carving and non-penetrating blind groove carving, thereby carving out various magical patterns with different shades, different textures, layers, and transitional color effects. With these advantages, laser engraving caters to the new trend of international clothing processing.

Let's introduce the application of CO2 laser engraving machines in the clothing industry in detail below.

Garment laser engraving machine

More than two-thirds of textile and apparel fabrics can be made with laser engraving machines to produce various digital patterns. The traditional textile fabric production process requires post-grinding, hot embossing, embossing, and other processing treatments, while the laser engraving machine burns in this respect has the advantages of convenient and fast production, flexible pattern change, clear images, strong three-dimensionality, and can fully express The natural color texture of various fabrics, and the advantages of long-lasting and new. If combined with the hollowing process, it will be the finishing touch and complement each other. Apparel fabrics and garment laser embroidery are suitable for: textile fabric finishing processing plants, fabric deep processing plants, ready-to-wear garment plants, surface accessories, and processing enterprises with supplied materials.

Cowboy image laser spray

Through the laser irradiation of the laser engraving machine, the dye on the surface of the denim fabric is vaporized, so that non-fading image patterns, gradual flower shapes, cat whiskers frosting, and other effects can be produced on various denim fabrics, adding new beauty to denim fashion. point. Laser engraving machine denim spray processing is an emerging processing project with substantial processing profit and market space. It is very suitable for denim garment factories, washing plants, processing enterprises, and individuals to carry out value-added deep processing of denim products.

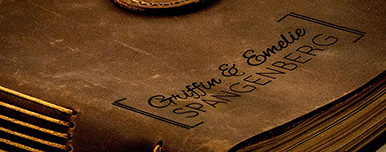

Leather fabric laser engraving machine logo

Laser engraving machine technology is currently widely used in the shoemaking and leather industries. The advantage of the laser engraving machine is that it can quickly engrave and hollow out various patterns on various leather fabrics, and it is flexible in operation, and it will not cause any deformation on the leather surface to reflect the color and texture of the leather itself. It has many advantages, such as high engraving accuracy, hollow out and no burrs, and arbitrary shape selection. It is suitable for the needs of processing manufacturers such as shoe uppers, shoe materials, leather goods, handbags, bags, and leather clothing.

Although laser engraving machine processing is also a thermal processing method, it is very suitable for cutting textile fiber fabrics due to the high focus of the laser, the slender light spot, and the small thermal diffusion zone. The specific performance is in the wide range of processing fabrics, smooth cuts without flash, automatic closing, no deformation, graphics can be designed and output by computer at will, no die, and so on. This makes laser processing a recognized alternative in the industry.

As a brand-new processing method, laser engraving machine processing has gradually been widely used in the leather, textile, and garment industries due to its advantages of precision, speed, simple operation, and a high degree of automation.