2019-11-26 20:22:23

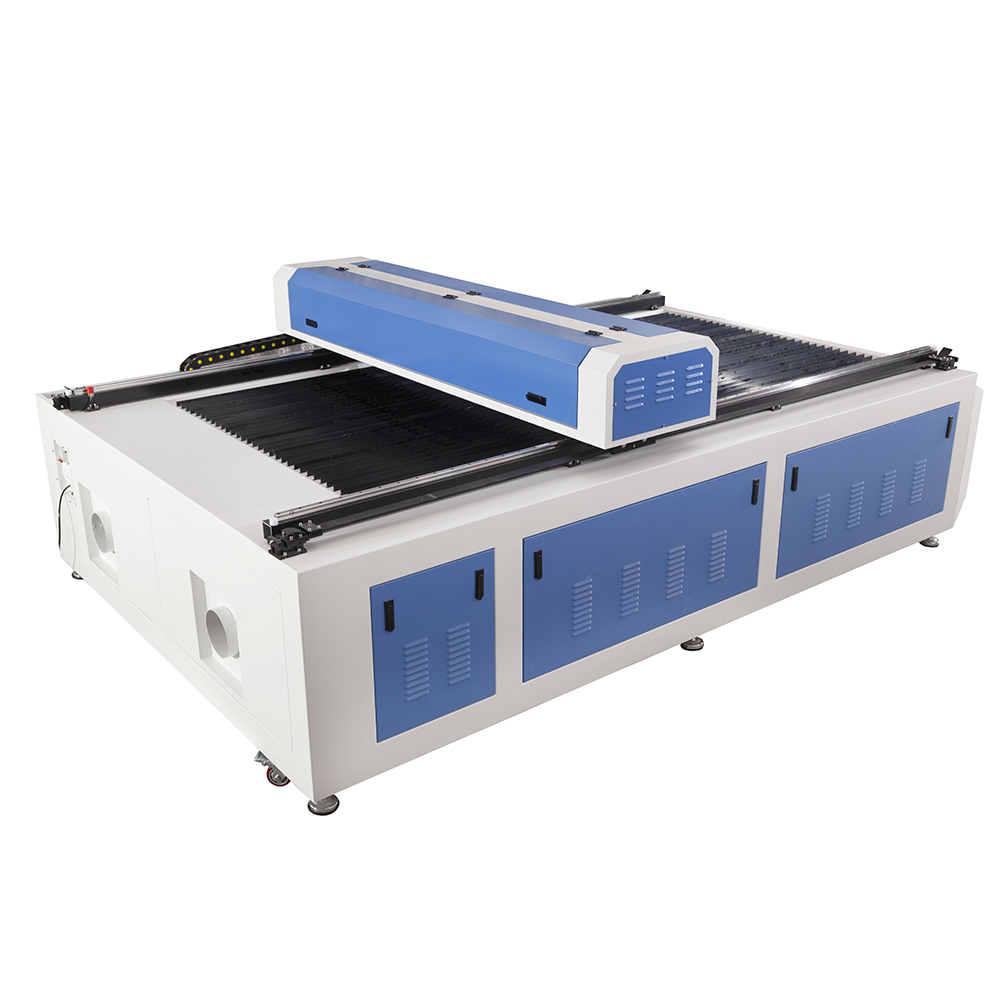

In the use of laser cutting machines, in order to safety protection and efficient production, the most important thing is the daily safety maintenance and maintenance of equipment. The following introduces the maintenance of important parts of the laser cutting machines.

1.Lubricating oil is added to the linear guide rail. The smoke and dust produced by the laser cutting machines for a period of time are corrosive to the guide rail, so it is necessary to maintain the guide rail regularly. Turn off the power supply of the laser cutting machine, clean it with a clean soft cloth guide rail, and then drop lubricating oil on the guide rail. After oil, let the slider roll back and forth in the guide rail to ensure that the lubricating oil enters the inside of the slider. After oil, let the slider roll back and forth in the guide rail, then we must first install the guide rail, pay attention to install the guide rail do not first fixed, to install all the fixing nails, maintain the level, in the belt and the slider fixed, then install the lens, dimming X to the end of the way to the destination.

2. Mirror, focusing mirror wipe. After using the laser cutting machine for a period of time, the smoke will adhere to the surface of the lens, affecting the cutting depth, but also affect the cutting accuracy. Generally, three pieces of mirror and one piece of focusing mirror are carefully wiped clean with anhydrous alcohol for about a week.

3. Oiling the bearing. Laser cutting machine uses a large number of bearings, in order to ensure a good cutting effect, some bearings need to be regularly refueled, wipe the dirt on the bearings with a clean soft cloth, use the needle to breathe the oil into the needle, and then slowly inject the bearing with the needle, slowly turn the bearing when the oil is injected.

4. Synchronous belt (belt) tension adjustment. There are several synchronous belts in the transmission system of laser cutting machine. If the synchronous belt is too loose, there will be a double shadow. If the synchronous belt is too tight, it will cause the synchronous belt to wear. After using for a period of time, please adjust the tension screw of the belt to adjust the belt to fit the tightness.

5. Laser tube maintenance. Laser tube is the use of circulating water cooling, long-term use down, there will be some white scale in the tube, we can add a small amount of vinegar in the circulating water, the water in the tube to get rid of, and then use clean water to clean the laser tube internal cycle so that the laser tube will be in the best working state, life will be extended.