Versatile Cutting: The laser head enables high-precision cutting of tubes, ensuring smooth, burr-free edges.

Auto-Focusing: Equipped with automatic focusing capabilities, the laser head adjusts the focus based on different materials and thicknesses, enhancing cutting efficiency and quality.

High power output: Provides stable high power output, suitable forcutting various types of pipes.

Superior Cooling: Advanced cooling system ensures the laser headdmaintains a stable temperature during prolonged operation,extending its lifespan.

Durability: Constructed with high-quality materials and craftsmanship.dthe laser head boasts long-lasting durability and high reliability.

Multi-Material Compatibility: Capable of cutting a wide range of metal materials, includingcarbon steel, stainless steel, aluminum, and copper, meeting diverse processing needs.

Modular Design: Simple, modular design makes the laser head easy to maintain and replace, enhancing equipment maintenance convenience.

Protective Lens: Equipped with high-quality protective lenses to effectively prevent damage from smoke and splatter during the cutting process.

01 HIGH PRECISION CUTTING:

The laser tube cutting machine ensures precise and clean cuts, reducing the need for post-processing.

It can handle intricate designs and complex geometries with ease.

02 EFFICIENCY:

Equipped with advanced automation features, it significantly reduces production time and labor costs.

The machine can cut tubes and pipes at high speeds without compromising on quality.

03 MULTIFUNCTIONALITY:

Capable of cutting a wide range of materials, including stainless steel, carbon steel, aluminum, brass, and copper.

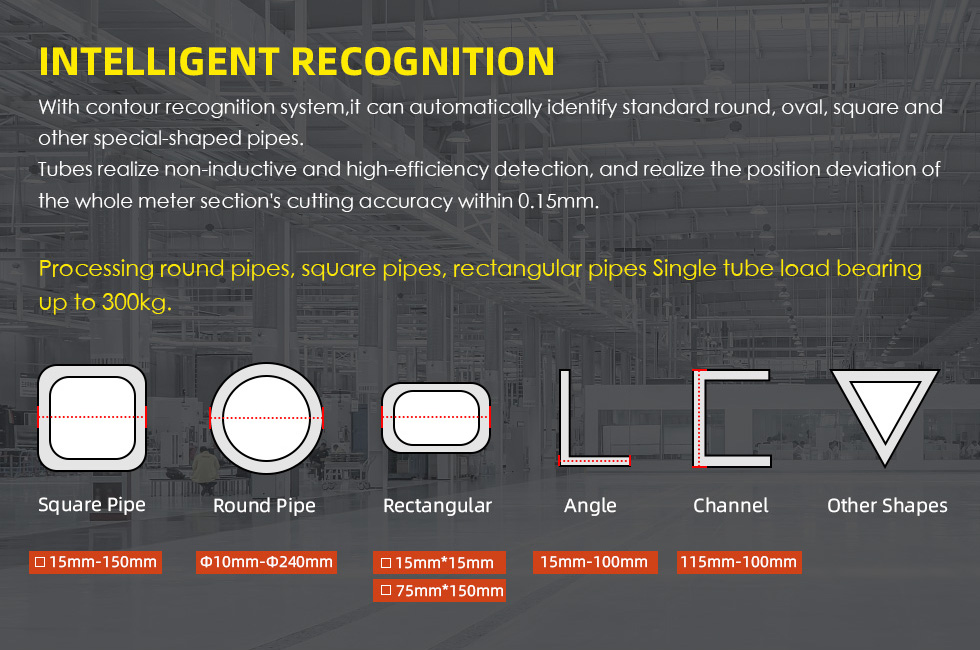

Suitable for cutting various shapes such as round, square, rectangular, and oval tubes.

04 AUTOMATED OPERATION:

Features like automatic loading and unloading, and intelligent nesting software optimize material usage and minimize wastage.

User-friendly interfaces and CNC control systems make the operation straightforward.

05 HIGH STABILITY AND DURABILITY:

Constructed with robust materials and components, ensuring long-term durability and minimal maintenance.

The machine's stability during operation ensures consistent cutting quality.

High Power and High Quality Laser Output. IPG /Raycus /MAX Fiber Source For Choose.

Servo motors stabilise and drive the beam to control the movementof the XYZ axis according to the programmed instructions tocomplete the cutting operations with complex precision,and the user can adjust the parameters according to their needs.

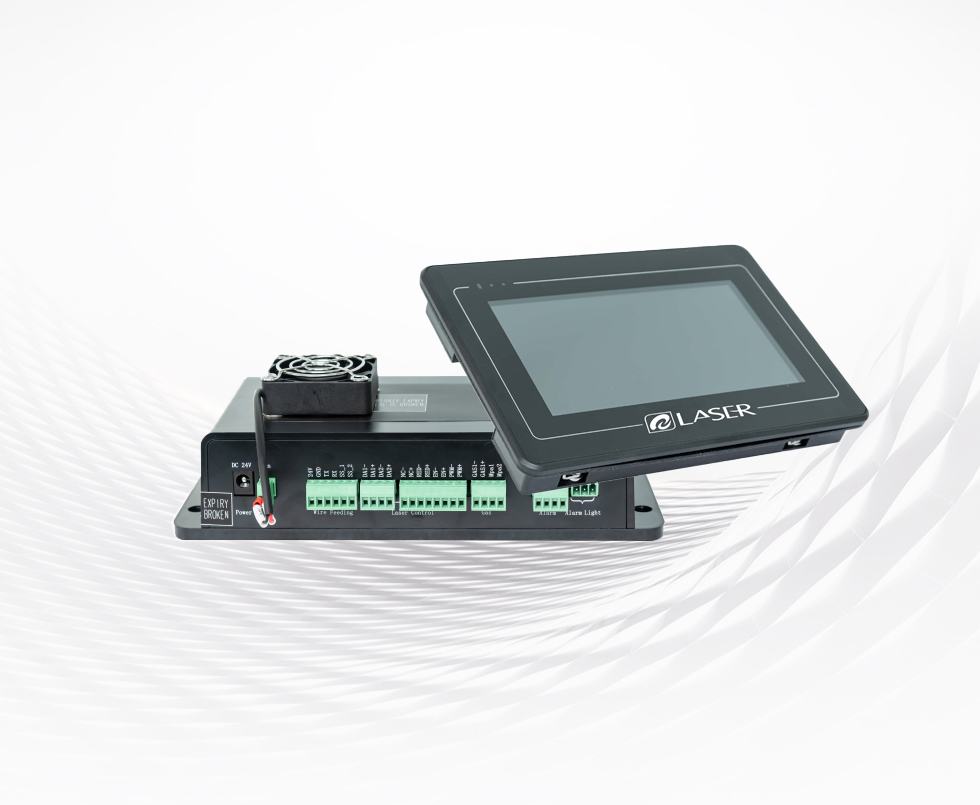

TubePro pipe cutting software With professional cutting software, fine cutting can be achieved by simple manipulation

Applications: The sheet metal laser cutting machine has extensive applications in decoration, infra-structure, construction, microelectronic, advertising, kitchen appliance, automobile andother equipment manufacturing, and other indusfries.

Applicable materials: Fiber laser tube cutting machine provides exceptional versatility, capable of working with a wide range of materials including carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized pipe, silicon steel fube, electrolytic pipe, titanium alloy, manganese alloy, etc.. It effortlessly handles various shapes and sizes of metal tubes, accommodating diverse project requirements.

Our machines can't do bevel cutting, 3D cutting, etc.

Our machine can not do zero tail material, the tail material is about 20cm.

| Model | FST-6024 Tube Fiber Laser Cutting Machine |

| Laser Power | 1500W 2000W 3000W 4000W(optional) |

| Working Area | 6000mm* φ10-240mm |

| Cooling Method | Water cooling protection |

| Positioning Accuracy | ±0.05mm |

| Maximum Acceleration | 1G |

| Maximum Rotational Speed | 85r/min |

| Machine Size | 7900*1740*2380(mm) |

| Table Maximum Load(KG) | 300KG |

| Control System | TubePro |

| Power Parameters | Three-phase AC 380V 50Hz |

| Laser Source | Raycus/Max/Reci/IPG |

PROFESSIONAL LASER