15 s Quick Change

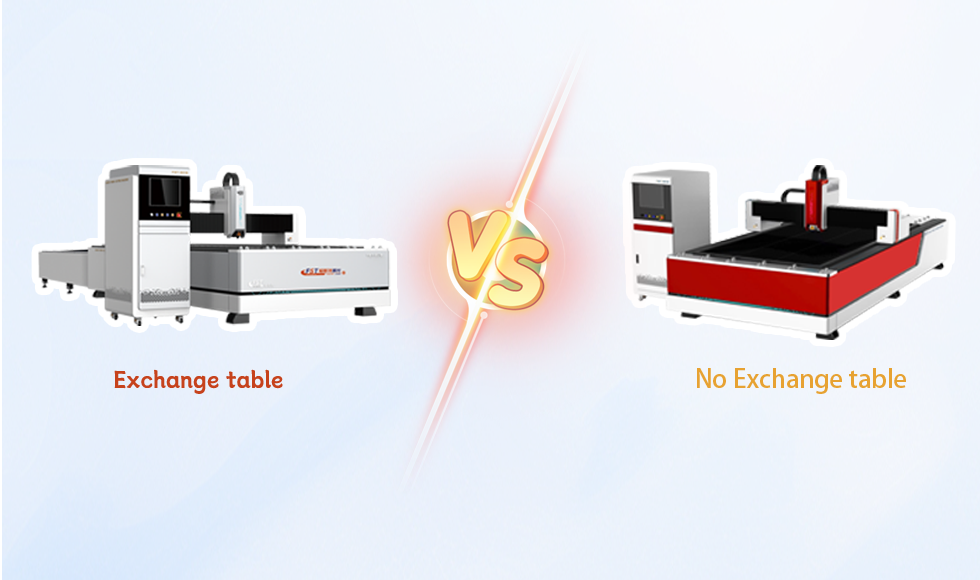

The exchange table is a critical component of the fiber laser cutting machine, consisting of two platforms and associated automation systems.This feature allows operators to swap work pieces on the alternate platform during the cutting process without halting operations. With the automatic exchange table system,operators can prepare the next work piece in advance,enabling continuous cutting,the exchange platform only takes 15 seconds for each exchange,operations and thus enhancing production efficiency while minimizing downtime.

Higher Production Efficiency

Equipped with an automatic exchange table system, it enables automatic table swapping and continuous processing, significantly boosting production efficiency.

Enhanced Flexibility

The exchange table allows for more flexible operations by preparing the next workpiece while the current one is being processed, reducing downtime and improving equipment utilization.

Diverse Processing Capabilities

Reduced Labor Costs

Improved Production Continuity

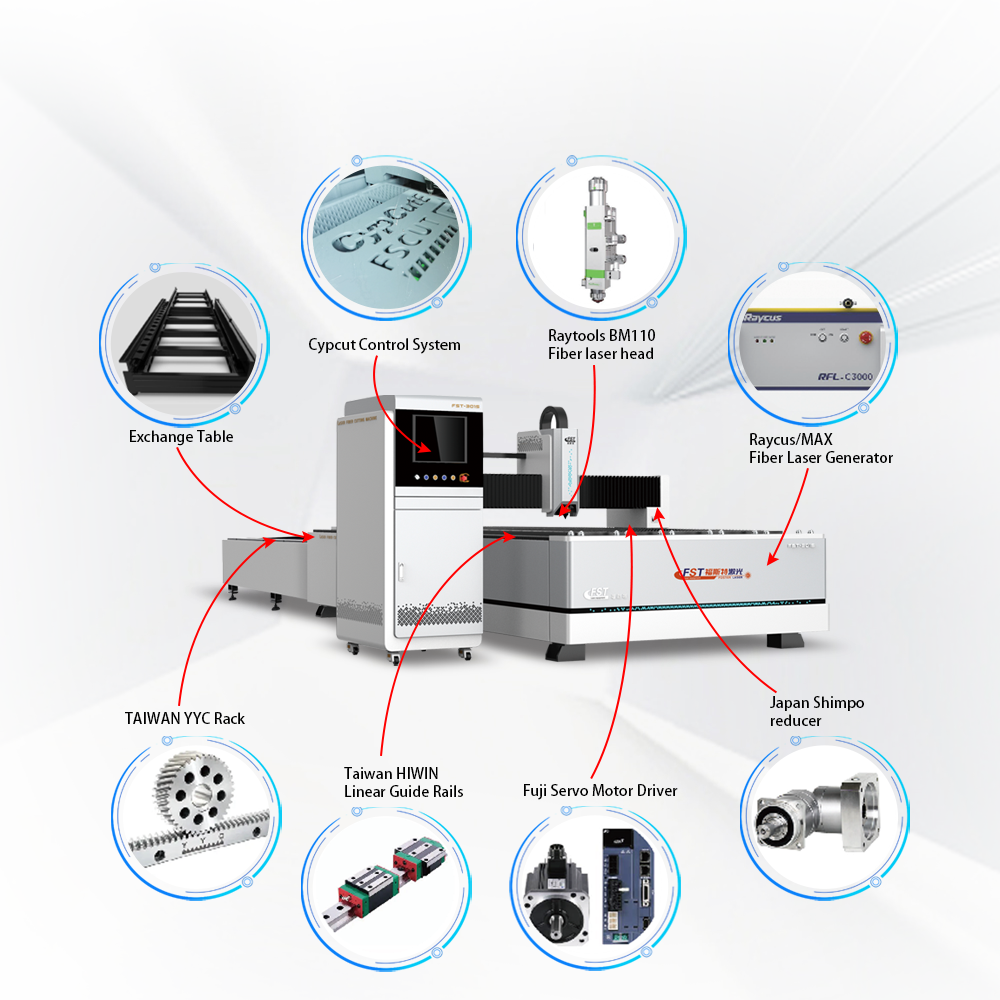

CypCut sheet cutting software is an in-depth design for fiber laser cutting industry. It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks.

1. Auto Optimize Imported Drawing

2. Graphical Cutting Technique Setting

3. Flexible Production Mode

4. Statistic of Production

5. Precise Edge Finding

6. Dual-Drive Error Offset

Multiple Protection High-precision Various Brands Of Laser Head Are Available

Monolithic cast aluminum beam High Speed More Efficient

Applications: Widely used in Metal processing industry, kitchen appliances, sheet metal chassis cabinets, mechanical equipment,electronic equipment, lighting hardware, advertising signs, automotive industry, auto parts, fitness equipment and other metal products, sheet metal cutting processing and other industries.

Applicable materials: Carbon steel, stainless steel, galvanized sheet, aluminum plate, brass copper, iron and its alloys most of the metal plate can be cut.

| Model | FST-3015E |

| Working area | 3000*1500mm |

| Laser Power | 2000W/3000W/6000W/8000W/12000W |

| Working table | 2(Exchanged) |

| Repeat Repositioning Accuracy | ±0.03mm |

| Accuracy of Positioning | ±0.02mm |

| Max Running Speed | 120m/min |

| Laser Source | MAX/Raycus/IPG |

| Maximum acceleration | 1G |

| Voltage | 380v three-phase 50hz |

| Graphic Format Supported | AI,MBP,Dst,Dwg,DXF,DXP,LAS,PLT |

PROFESSIONAL LASER