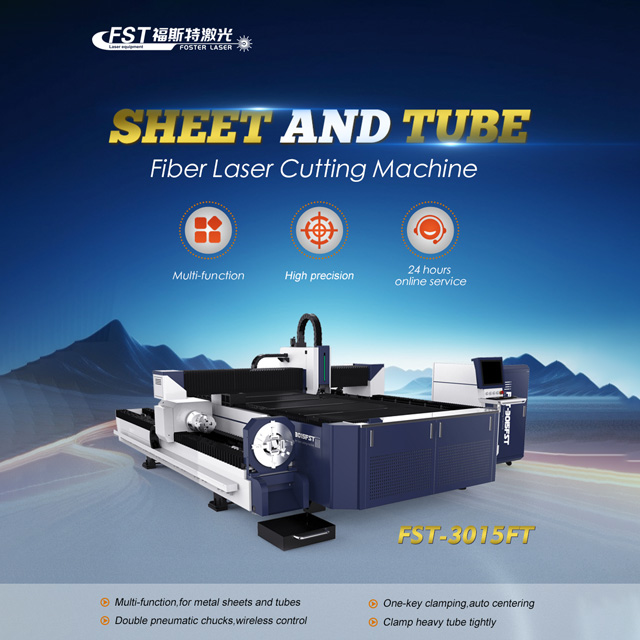

Dual-Purpose Functionality

Capable of cutting both tubes and plates,meeting various processing needs.

Cost Reduction

Lowers the cost of purchasing and maintaining multiple machines,reducing overall equipment investment.

Efficiency and Space Saving

Saves on transportation costs and usage space,significantly improving work efficiency.

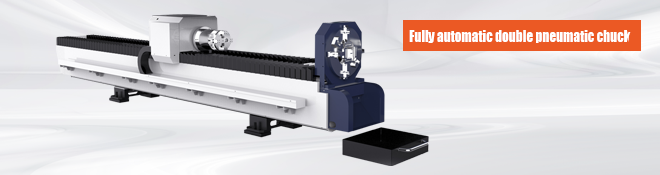

Advanced Clamping System; Durable Construction

15 s Quick Change

The exchange table is a critical component of the fiber laser cutting machine, consisting of two platforms and associated automation systems.This feature allows operators to swap work pieces on the alternate platform during the cutting process without halting operations. With the automatic exchange table system,operators can prepare the next work piece in advance,enabling continuous cutting,the exchange platform only takes 15 seconds for each exchange,operations and thus enhancing production efficiency while minimizing downtime.

CypCut sheet cutting software is an in-depth design for fiber laser cutting industry. It simplifies complex CNC machine operation and integrates CAD. Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks.

TubePro designed for professional tube cutting, supports production of tube and profile of various shape. It works with Tubes nesting software seamlessly to realize technique setting, advanced toolpath generation and nesting for standard and special production need.

One-click chuck opening Pneumatic open clamp Special support frame

No deformation,light weight,high strength Light cross beams allow equipment to operate at a faster rate boosting processing efficiency and quality.

Auto-Focusing: Equipped with automatic focusing capabilities,the laser head adjusts the focus based on different materials and thicknesses, enhancing cutting efficiency and quality.

Applications: Automotive Industry, Aerospace, Construction and Architecturek Metal Fabrication,Agricultural Machinery, Shipbuilding, Oil and Gas, Electrical Equipment, Medical Equipment, Renewable Energy.

Applicable materials: Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, Titanium, Galvanized Sheet, Silicon Steel, Galvanized Steel Sheet, Other Metal Alloys.

| Model | FST-3015 Dual-use Sheet & Tube Fiber Laser Cutting Machine |

| Laser Power | 1500W/2000W/3000W/6000W/8000W/12000W |

| Working table | Sheet and Tube |

| Cutting head | Raytools/Precitec/WSX/OSPRI |

| Max Running Speed | 120m/min |

| Maximum Acceleration | 1G |

| Laser source | Max/Raycus/IPG |

| Voltage | 380V three-phase |

| Graphic Format Supported | AI,BMP,Dst,Dwg,DXF,DXP,LAS,PLT |

| CNC System | TubePro & Cypcut |

PROFESSIONAL LASER