2019-11-26 18:42:02

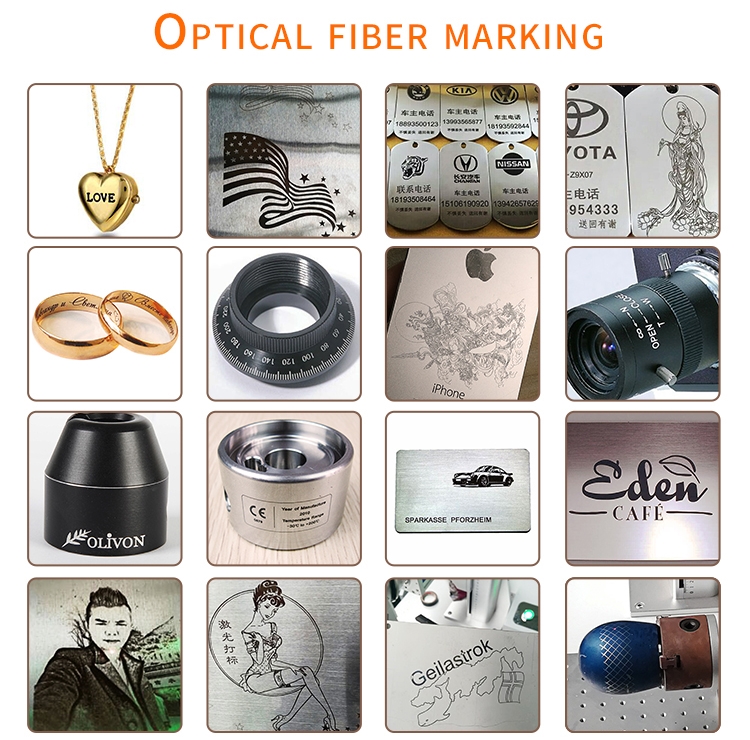

Daily maintenance and fault troubleshooting of fiber laser marking machine

1. Matters needing attention

The laser is a air-cooled laser, and the working environment (room temperature) is required to be between 10℃ -35℃ (25℃ is the best).

(2) Do not bend the fiber. If you need to bend, make sure that the minimum diameter of the bending circle of the fiber is more than 20 cm

(3) When there are abnormal phenomena, first turn off the laser power supply and galvanometer power supply, and then check

2. Daily maintenance

It is recommended to clean the lenses before work every day. The equipment should be turned off

To clean the focusing mirror, gently unscrew the focusing mirror from the frame, bend the mirror wiping paper into several folds, wet it with cleaning liquid, and use

The wet lens paper is rubbed onto the lens surface several times until the mirror surface is clean and free of dust and grease.

(2) regularly clean the machine surface and internal dust, to ensure internal cleaning.

Common fault troubleshooting

A. It can't be turned on

Check whether the power is switched on

Check if the air switch is closed

B. Marking without light, red light does not show

Check whether the laser control line on the USB board card is loose

Check whether the 24V switching power supply of the laser is normal

Check whether the laser cooling fan works normally

C. Air switch trip

The main circuit is damaged by components

D. The galvanometer does not move, or does not move in one direction

Check that the galvanometer XY status indicator is normal

Check whether the galvanometer wire is loose

Check whether the galvanometer switch power supply is normal

Check whether the output signal of USB card galvanometer is normal

our company as a fiber laser marking machine supplier in China ,provide fiber laser marking machine ,if you need that pls contact us.