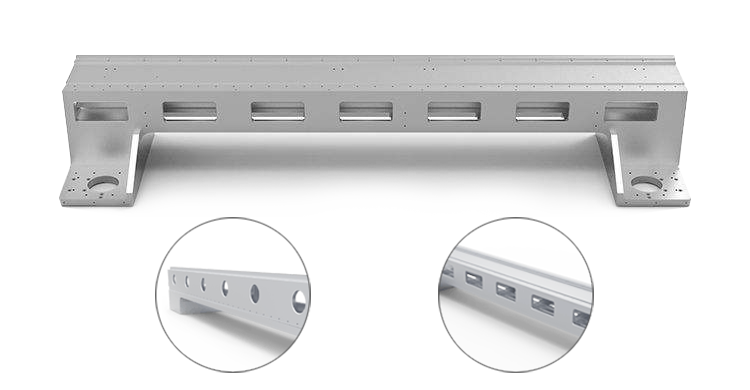

It is manufactured with aerospace standards and formed bypress extrusion molding. Aviation aluminum has many advantages, such as good toughness, lightweight , corrosion resistance, anti-oxidation, low density, and greatly increasehe processing speed.

High speed

The light crossbeam can ensure the machine have high moving speed and improve the processing efficiency.

More efficient

The aluminum profile beam of the aerospace industry makes the equipment have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

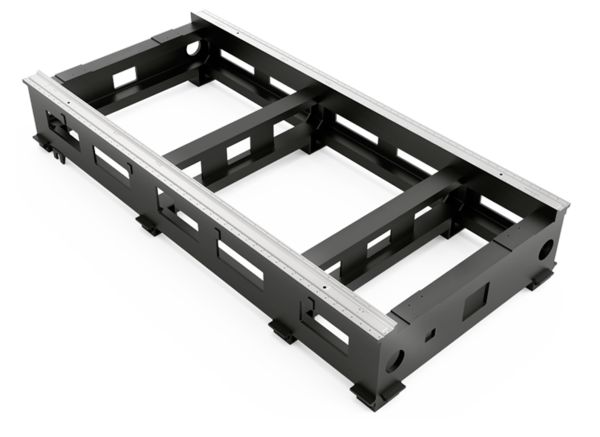

Flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using.

Lifetime service

It ensures the accuracy of the machine working for a long time, and it will not deform during its lifetime use.

Higher precision

A solid bed has high stability .It is unmatched by other materials and structures. The use of graphite cast iron as a raw material keeps the precision of the machine tool for a long time and remains unchanged for 50 years. The rough, fine and super-fine of the imported gantry machining center guarantee the machining accuracy requirements of the machine body.

Fiber laser generator with great and stable performance

The laser source to have lifespan ove100,000 hours .

Raycus / Max / JPT for choice .

The USA IPG Laser source is optional

Long use lifetime and accurate route moving, with low noise when the machine is processing the metal materials, After many refinements, it has small size ininstallation but high precision function.

Dual rail and rac, world famous imported brand, precision linear guides and imported gear racks

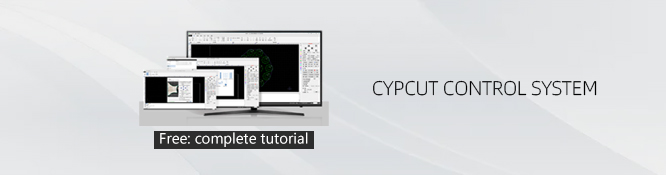

The best control system in fiber laser machine industry .It is suitably applied to high power fiberlaser machine and can support the rotary device, exchange table and automaticfocus cutting head.

Advertising logo industry, Kitchen appliances, Hardware and Lighting, Aerospace, Environmental protection machinery, Refrigeration equipment, Mechanical equipment, Cabinet body, Sheet metal industry, Electronic appliances, Subway accessories, Confidential, Accessories, Automobiles, Ships, Metallurgical equipment, Household appllances, Crafts, Gifts, Tools, Processing, Decoration, Advertising, Metal processing, etc

| MODEL NO. | FST-1530 |

| Processing area | 1500mm*3000mm |

| Fiber power | 1000W/1500W/2000W/3000W/6000W/8000W |

| Cooling mode | Water cooling and protection system |

| Resetting positioning accuracy | ±0.01mm |

| Max acceleration | 1G |

| Compatible Software | CorelDraw/AutoCAD/Photoshop/AI … |

| Max traveling speed | 110m/min |

| Driver system power | Y=750W; X=750W; Z=400W |

| Support graphic format | LXD/.DXF/.PLT/.AI/.Gerber/.DWG …. |

| Transmit system | Dual Rack & Pinion type |

| Operating temperature | 0-45℃ |

| Operating humidity | 5-95% |

| Option | Rotary attachment for column materials |

PROFESSIONAL LASER