No Water Cooling Required

Utilizes an air-cooling system instead of the traditional water-cooling setup, reducing equipment complexity and dependence on water resources.

Ease of Maintenance

Air cooling systems are easier to maintain than water cooling systems, lowering long-term operational costs and maintenance efforts.

Strong Environmental Adaptability, Portability, High Energy Efficiency, User-Friendly Operation, Versatile Applicability, High-Quality Welds etc.

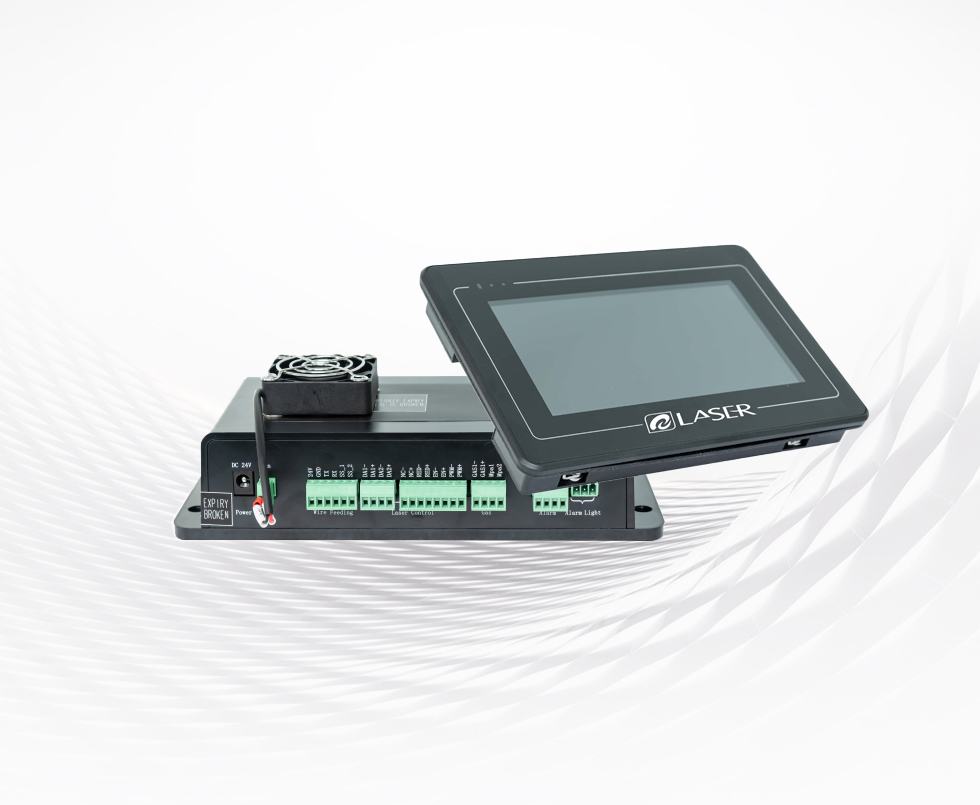

Foster laser provides Relfar, Super chaoqiang, Qilin, Au3Tech 4-in-1 operating system with high performance, intuitiveness, and ease of use. It can not only provide good weld results but also provide good cleaning and cutting results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

Low Suitable for lasers with low to medium power

Simple, no complex cooling system

Fast, almost no need to warm up

Not limited by water resources, More suitable for mobile use and harsh environments

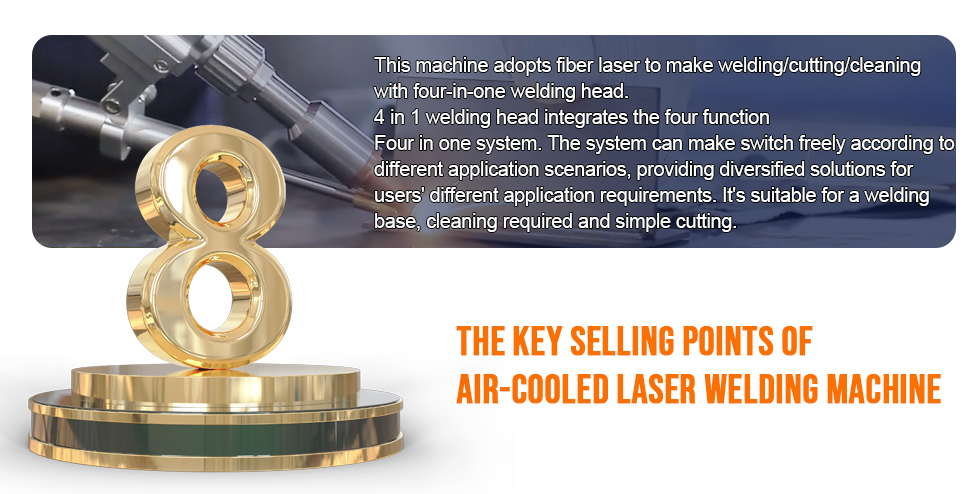

The 4 in 1 laser welding cleaning cutting machine can not only clean the metal surface contaminants,but also weld and cut various metal materials.

It is a multi-functional laser equipment. And it has three modes of welding cleaning and cutting, which can be flexibly switched.

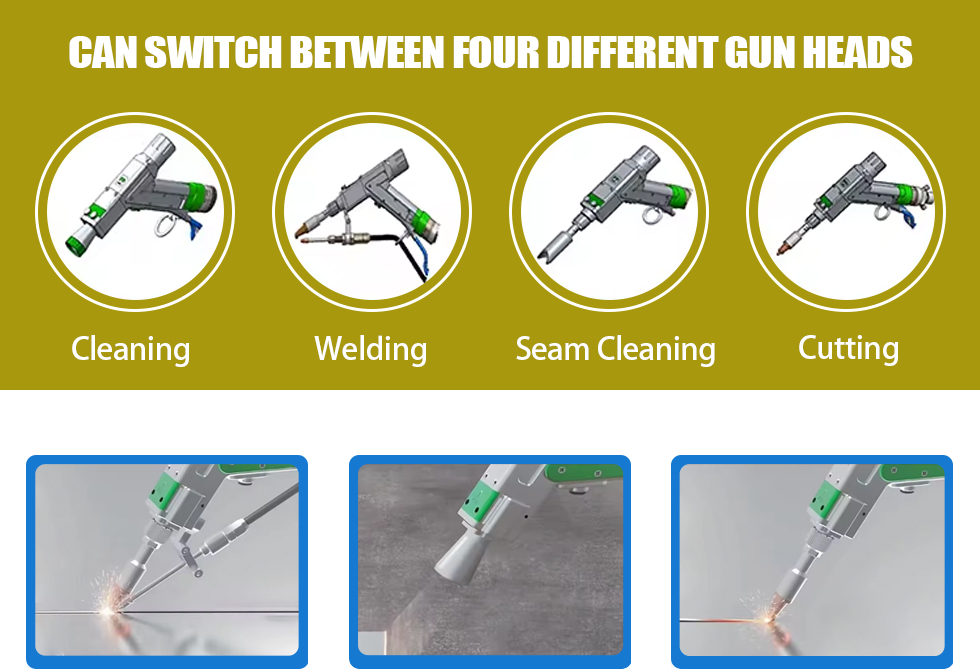

4 in 1 welding head integrates the four function Four in one system.

The system can make switch freely according to different application scenarios, providing diversified solutions for users' different application requirements. It's suitable for a welding base, cleaning required and simple cutting.

Standard accessories for laser nozzles.supporting external, internal, flat, wire feeding, cutting, and seam cleaning

Air cooling systems are easier to maintain than water cooling systems, lowering long-term operational costs and maintenance efforts.

Application Area:Automotive Manufacturing, Aerospace, Electronics and Microelectronics,Medical Devices, Jewelry Industry, Energy Sector,Mechanical Manufacturing, Piping and Structural Engineering

Application materials: Stainless Steel, Carbon Steel, Aluminum and Aluminum Alloys, Copper and Copper Alloy, Titanium and Titanium Alloys, etc..

| Model | FST-A1150(FST-A1250/FST-A1450/FST-A1950) |

| Operating Mode | Continuous Modulation |

| Cooling Mode | Air Cooling |

| Power Requirements | 220V±10%50/60Hz |

| Machine Power | 1150W(1250W/1450W/1950W) |

| Welding Thickness | Stainless steel 3mm Carbon steel 3mm Aluminium alloy 2mm |

| Gross Weight | 37KG |

| Fiber length | 10m(standards) |

| Machine Size | 650*330*550mm |

PROFESSIONAL LASER